News & Media

NEWS

Major pump manufacturers are relying on AMPO’s aftermarket service to manufacture complete machined pump components such as impellers, diffusers, suction bells, column pipes, bearing housings, chambers and bowls with really short delivery times.

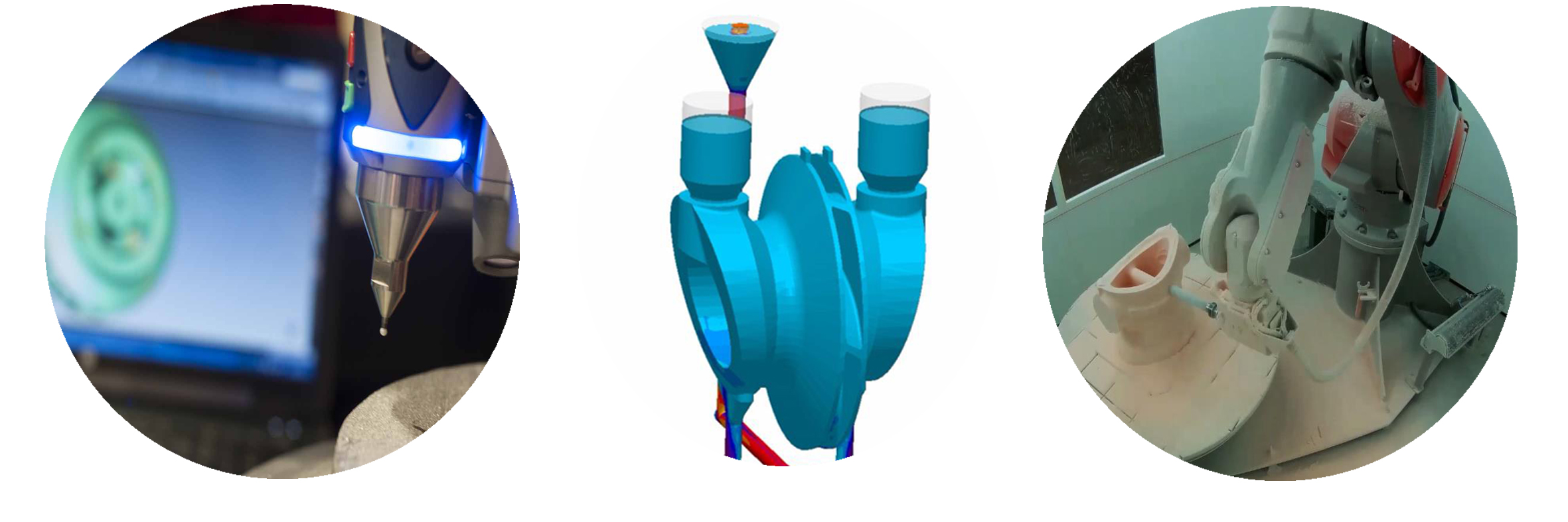

At AMPO clients can find the most updated know-how and engineering services, including Reverse Engineering and Magma Soft simulations to offer and achieve reliable aftermarket pump solutions.

In the manufacturing of pump components for the aftermarket sector, AMPO implements the latest patternless casting technology in order to obtain high quality castings with dimensional accuracy and improved quality surface finish. With this patternless casting method, ceramic shells are produced in AMPO within a day.

Moreover, once the components are produced, AMPO FOUNDRY has an in-house laboratory and the latest NDT facilities (3D Dimensional Control, X-ray, Dye penetrant tests, magnetic particles, ultrasonic tests, PMI, etc.) in order to ensure the reliability of pump components.

AMPO also offers customized services such as pressure tests, balancing, pre-assembly and painting of components.

AMPO team guarantees a prompt response to customer needs wherever they may be; the organization has a clear orientation towards the development of components with short delivery requirements. Pump assemblies in West Africa, Middle East, USA, China and India are currently being powered using AMPO components.