Processes

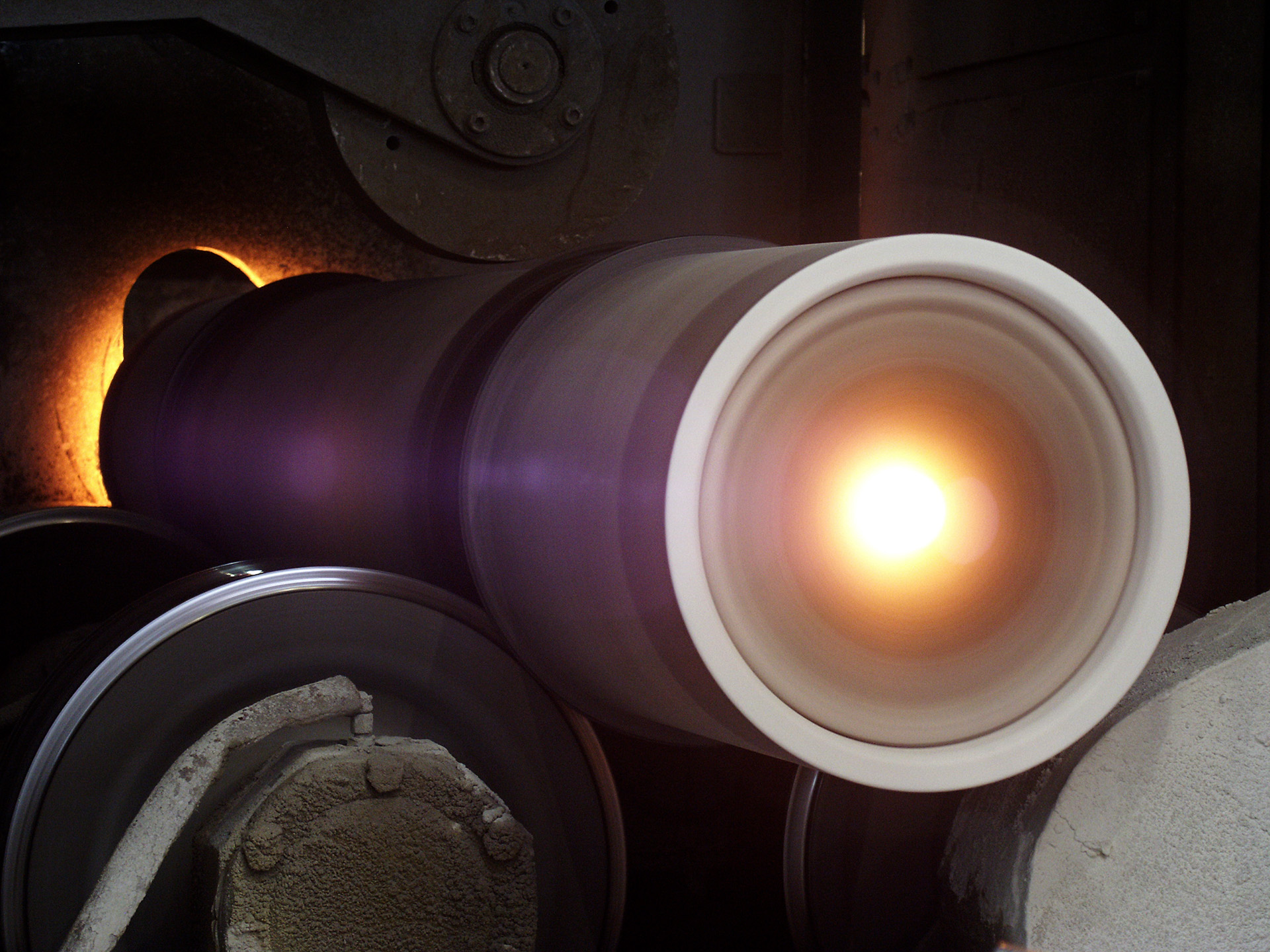

Centrifugal casting

Casting process using a metal die which spins at high speed. Once the molten metal is in the die, centrifugal force pushes the solidifying steel onto the surface of the mold. We have facilities for both horizontal and vertical spinning. Horizontal spinning covers 100-670 mm external diameter and vertical spinning 430-1,300 mm.

Centrifugal casting

AMPO machines and finishes all types of parts with round geometries. The process starts with cast dimensions adjusted to the finished required measurements, in order to reduce weight and be in a position to offer customers more competitive products.

AMPO produces a range of tubes with an external diameter of between 100 and 670 mm, and lengths of between 2,100 and 3,000 mm.

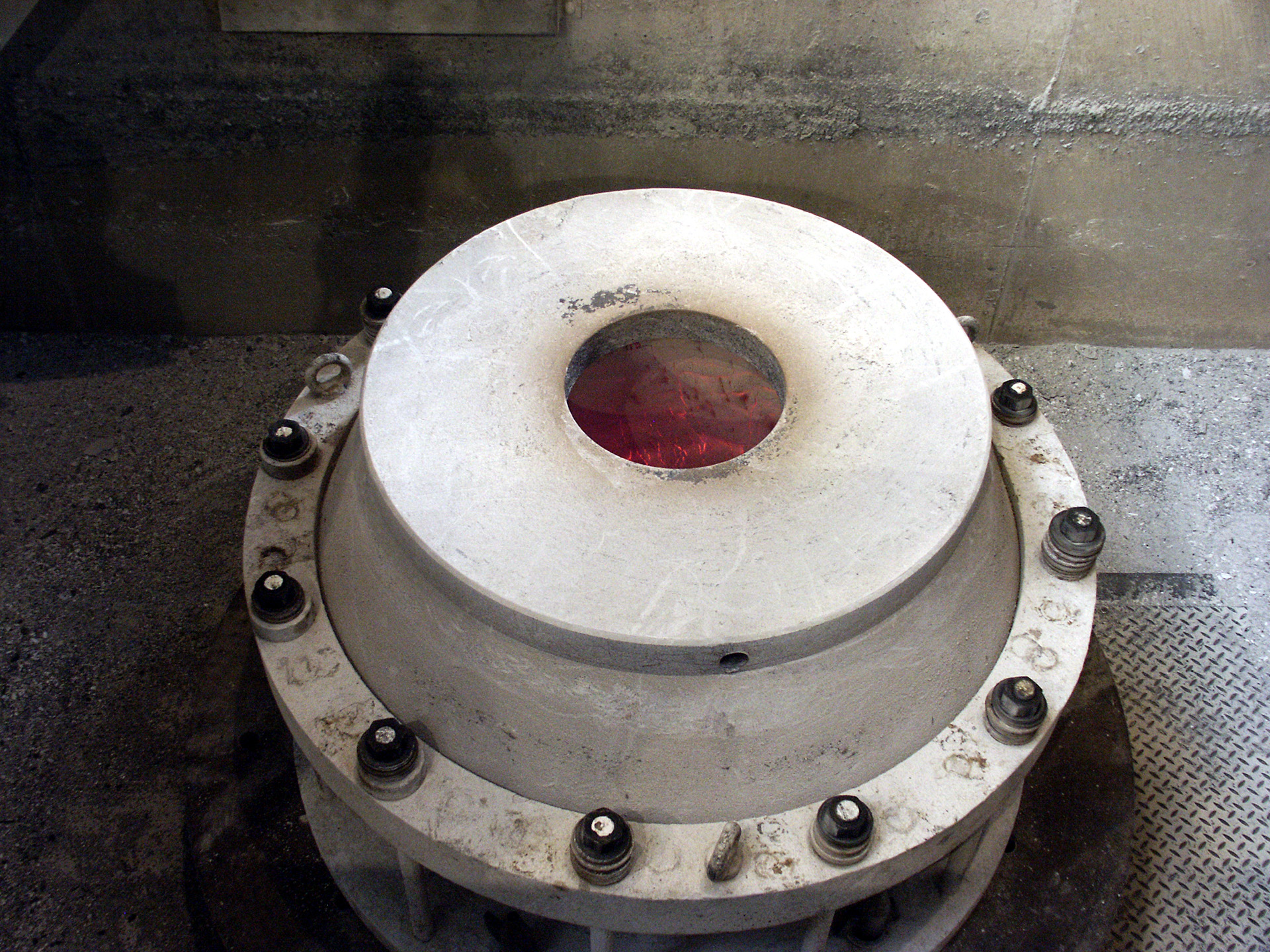

We have three vertical machines, capable of making rings/tubes with external diameters of between 430 and 1300 mm, and balls from DN300 (12”) to DN900 (36”).

Shaped centrifugal casting (SCC)

A process developed from Centrifugal Castings, using different tools and techniques to generate complex external geometries.