News & Media

NEWS

A European-based American compressor manufacturer has trusted in AMPO FOUNDRY for the manufacture of a significant number of half-finished compressor castings.

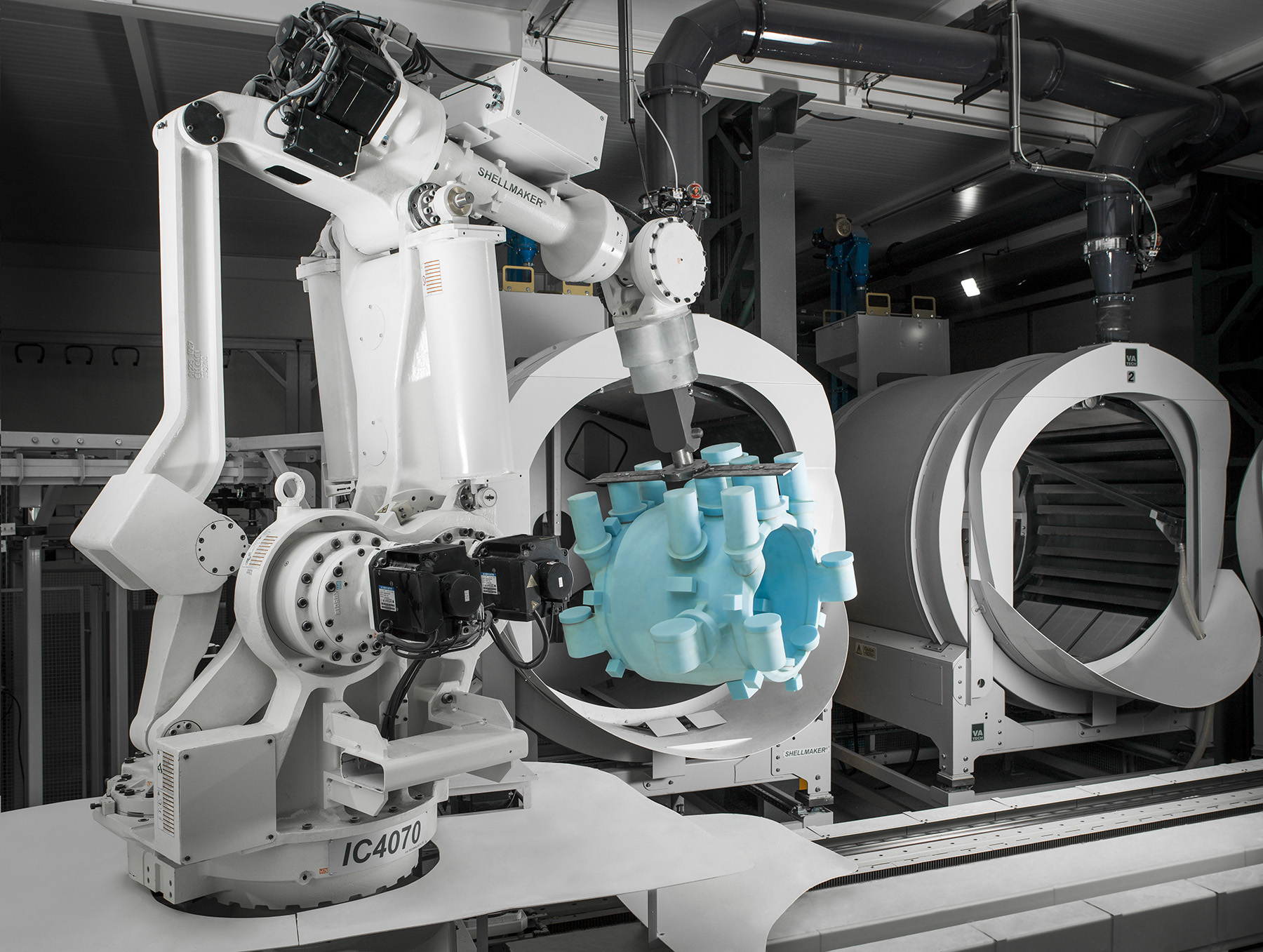

In order to offer customers the widest possible range of castings and best solutions AMPO has 4 production lines: Sand Moulding, Ceramic Moulding, Shaped Centrifugal Casting (SCC) and Centrifugal spinning.

For the development and manufacturing of these compressor castings AMPO has used the Ceramic Moulding Technology, which enables the company to offer large cast components as well as complex geometries. This Moulding technology is moreover highly automatic, and this has enabled it to increase its competitiveness.

All these compressor castings have been tailor made in order to meet the requirements of the American customer. In addition to this, it should be noted that for the compressor manufacturer Service was a key factor in this project, and through AMPO’s “patternless” technology, both supplier and customer have been able to fulfill their commitments regarding to delivery times. Few months ago, so short delivery times were unimaginable.