AMPO FOUNDRY, an international leader in stainless steel and high alloy castings, has recently supplied around 100 pump castings in superduplex (Gr5A) for BARKA DESALINATION project, a consortium gathering SUEZ and its partners in order to finance, construct and operate a sea water desalination plant in Barka (Oman).

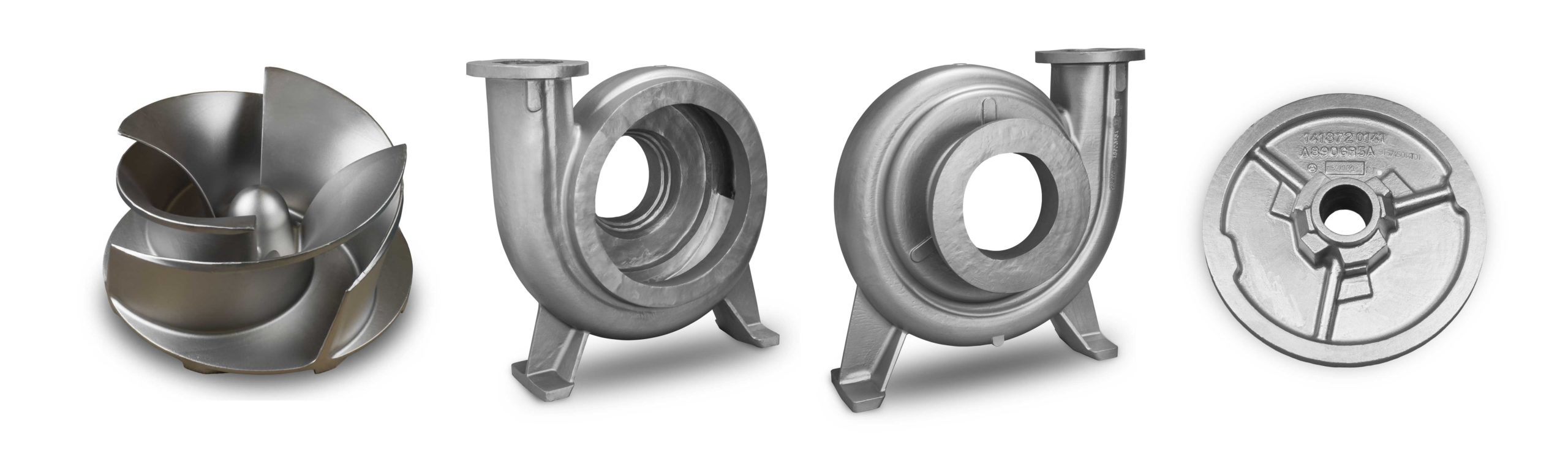

The customer, a worldwide pump manufacturer, has trusted in AMPO FOUNDRY for the manufacturing of 100 pump castings such as impellers, volute bodies, side plates, etc.

The weight of whole the components come to 30 tonnes.

AMPO has a wide experience in the manufacturing of superduplex (Gr5A) components and it has the NORSOK certificate for whole the moulding processes. It also should be noted that it has three heat treatment furnaces with a capacity of 8 tonnes, which are also approved to NORSOK standards. It has been all this, together with the Ceramic Moulding process, which has made the customer entrust the development of all these pump castings to AMPO.

The Ceramic Moulding process is the ideal production line to obtain excellent surface finishes, which in turn is essential to achieve an optimum pump performance.

In order to offer customers the widest possible range of castings and best solutions AMPO has 4 production lines. For the development and manufacturing of these pump components for the project in Barka, AMPO has used 3 of these processes: sand moulding, ceramic moulding and centrifugal spinning. Each line uses the most advanced technologies on the market and it is important to mention that, for example, AMPO has recently proceed with the automation of the Ceramic Moulding process, which has enabled AMPO to start offering large cast components and complex geometries through this process. This automation has also enabled it to increase its competitiveness.

On the other hand, in order to ensure the reliability of all these pump castings, AMPO has carried out the following Non Destructive Tests: X-ray, dye penetrant tests, magnetic particles, ultrasonic tests, picking and 3D dimensional control.

The reverse osmosis desalination plant in the Sultanate of Oman will start supplying potable water in April 2018, which will have a capacity of 281,000m3 per day.