A French valve manufacturer has trusted in AMPO FOUNDRY for the manufacture of a significant number of high added value safety valve castings for an important refinery in China, a project that is being executed by a leading Italian EPC. This contract award will be the largest contract ever signed in AMPO FOUNDRY’s 56 years history.

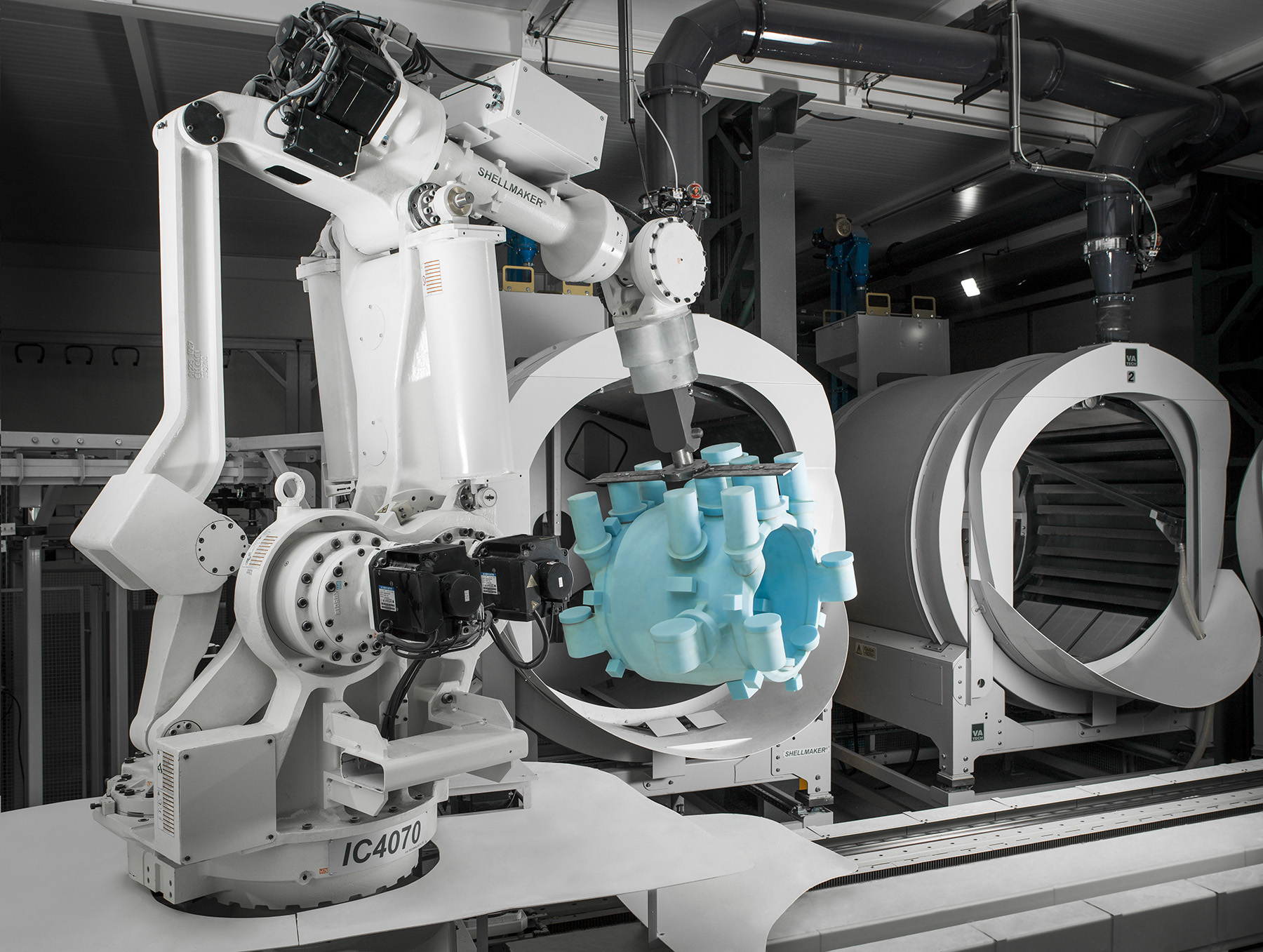

For the development and manufacturing of a total amount of 642 valve body castings and 160 valve piston castings, AMPO FOUNDRY will use its cutting-edge Sand Moulding and Centrifugal Spinning production technologies. In its Sand Moulding facilities, with a monthly production capacity of approximately 340 tonnes, AMPO can produce up to 5 ton castings and on the other hand, in its Centrifugal Spinning facilities, with a monthly production capacity of 450 tonnes, it covers 100-670mm external diameter in horizontal spinning and 430-1200mm external diameter in vertical spinning.

The weight of the valve castings will vary from 24 kgs to approximately 1 ton.

Moreover, some of the valve components will be machined on our brand-new machining facilities, where we have the most intelligent machine tools, together with weld overlay cladding technologies. Furthermore, due to the high criticality degree of those safety valve castings, exhaustive tests will also be performed by approved laboratories in order to guarantee castings’ complete reliability.

The highest technology capabilities and the already proven working experience will enable AMPO to comply with the very demanding lead-time on this project.

Safety valves must provide outstanding performance and exceptional reliability to customers for the most critical and severe applications. Consequently, it is important to count on an integrity foundry’s collaboration. AMPO FOUNDRY is an expert in high added value castings and it has a wide experience in casting development for severe service applications.

At AMPO FOUNDRY customers can find the most updated know-how and engineering services, offering the most reliable high added value castings.