AMPO and CTI (Castings Technology International) have signed a collaborative agreement whereby CTI will provide consulting services as well as functional advice to AMPO in order to provide higher added value to AMPO Foundry’s customers.

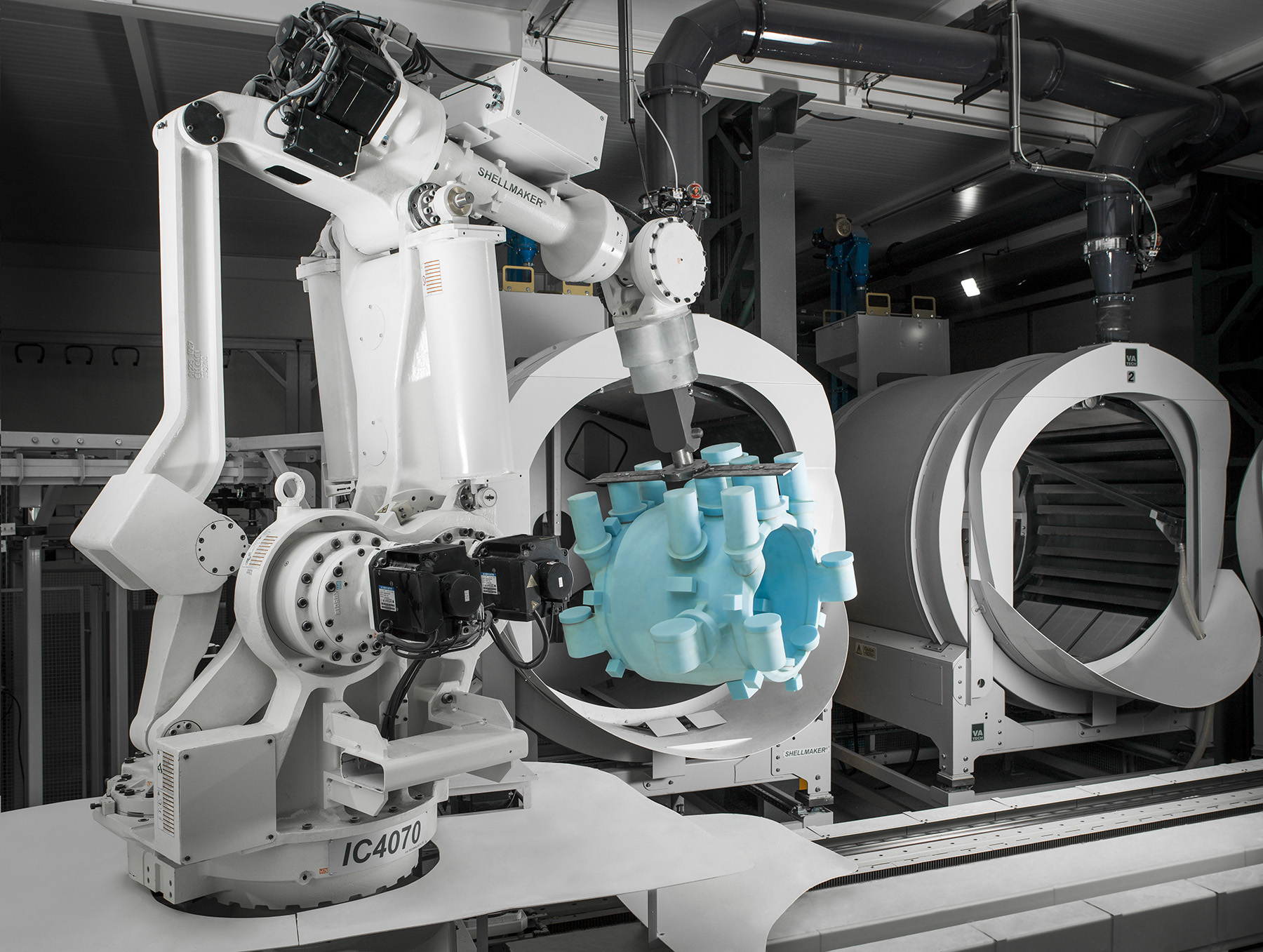

This agreement will help AMPO to continue to offer the most innovative and reliable solutions in the market to its customers, working together with CTI to further the development of several improvement and research lines including Ceramic Moulding, Shaped Centrifugal Castings (SCC), high alloy steels, patternless technology, production of bronze castings, etc.

AMPO FOUNDRY, which is based in Idiazabal, Spain and is a leader in service and the development and production of special material castings, has trusted in CTI due to its knowledge and experience in the development of advanced casting solutions. With this agreement AMPO, foresees a technological leap forward, applying the knowledge and methodology that CTI has previously implemented in sectors such as aeronautics, and optimizing its processes in terms of quality, service and cost.