AMPO FOUNDRY, an international leader in stainless steel and high alloy castings, has collaborated with a leading screw pumps manufacturer on the complex geometry castings development for a new sealed twin screw pump for chemical and petrochemical sectors.

This new and innovative pump has been recently launched in ACHEMA exhibition and it eliminates the need for mechanical seals and complex seal supply systems, and enable customers to handle harmful substances without polluting the environment. AMPO FOUNDRY has produced high added value castings for this innovative screw pump.

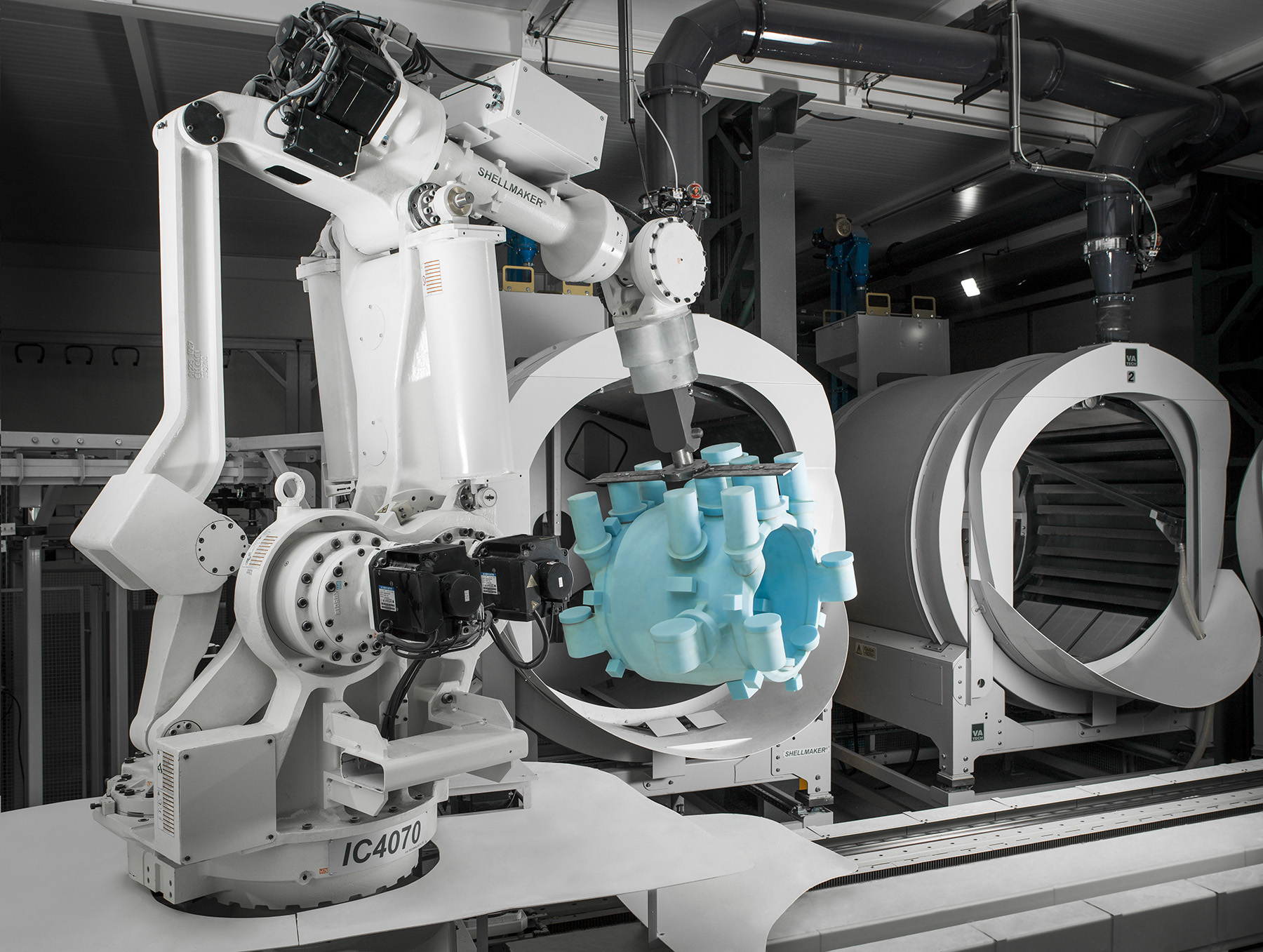

For this project, the parts have been produced in our brand new automated Ceramic Moulding facility. The automation of this process has allowed AMPO to increase its competitiveness, offering a capacity of up to 240 tonnes per month and 60 parts a day.

Moreover, all of the components can also be fully-machined on a brand new 5 axis machining center with FMS (Flexible Manufacturing System).

AMPO FOUNDRY is an international leader in the development of customized and high added value castings for pumps, valves, marine and power generation.